Process Technology

Information

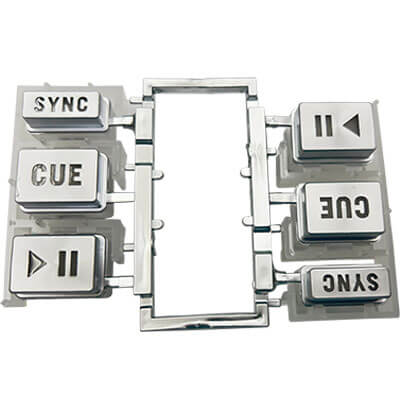

ABS Electroplating Technologies

Hsin Chang specializes in modifying the surface properties of ABS plastic through advanced electroplating. Our process enhances aesthetics, electrical conductivity, wear resistance, and corrosion protection. We offer a full range of ISO-certified finishes from Bright Chrome to RoHS-compliant Trivalent Chrome.

Surface Finishing Capabilities

Bright Chrome

- Process: Multi-layer plating (Copper/Nickel/Chrome).

- Appearance: High-gloss, mirror-like metallic finish.

- Application: Luxury automotive grilles, door handles, and sanitary fittings.

Trivalent Chrome (RoHS Compliant)

- Process: Hexavalent-chromium-free eco-friendly plating.

- Compliance: Fully meets EU RoHS and REACH directives.

- Benefit: Balancing environmental friendliness and product performance, it maintains a bright metallic appearance while delivering excellent corrosion resistance.

Satin / Matte Nickel

- Appearance: Non-reflective, velour, or pearl-like texture (Pearl Nickel).

- Function: Resistant to fingerprints and glare.

- Application: Interior automotive trim and home appliance control knobs.

Brushed Finish (Hairline)

- Definition: A surface treatment technique in which a metal layer is plated onto a plastic substrate, followed by mechanical grinding or brushing to create a unidirectional texture, and finished with a clear coat.

- Effect: Creates a fine, metal-like hairline texture on the plastic surface, enhancing the tactile layering and overall design aesthetics of the product.

Advanced Manufacturing Techniques

- Double-Shot Plating: Utilizes double-injection molding to bond plateable and non-plateable resins, creating precise two-tone components without secondary assembly.

- Selective Plating (Masking): Applies insulating masking to specific areas, allowing for functional non-conductive zones on plated parts (ideal for electronics).

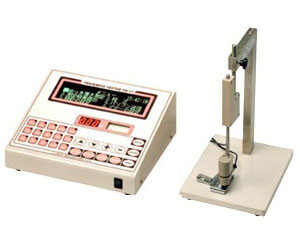

Reliability & Quality Testing

Xinzhuang’s internal laboratory conducts relevant tests in accordance with ISO / ASTM international standards as a reference for evaluating the product’s service life performance under extreme environmental conditions.

| Test Item | Methodology | Purpose |

| CASS Test | Copper-Accelerated Acetic Acid Salt Spray | To verify Corrosion Resistance for harsh environments (e.g., exterior auto parts). |

| Thermal Cycle Test | Cycling between -30°C and 70°C | To ensure plating adhesion under Thermal Stress (no peeling/cracking). |

| Cross-Cut Test | Standard tape adhesion test | To validate the Bond Strength between the metal layer and plastic substrate. |

| Coating Thickness Test | Constant Current Electrolytic Method (Voltage Change Detection) | To verify that the coating thickness meets specification and quality requirements, and to ensure consistency and stability of different metal coatings. |

Require specific testing standards (ASTM/ISO) for your project?

Our in-house lab ensures your parts meet strict global requirements.